- bearings

- spherical bearings

- engineering plastics

- friction material

- insulation material

The offshore, shipping and dredging industries have certain aspects in common, such as the environmental climate and vessels. This is why we have combined them into a single sector, namely the Maritime Sector.

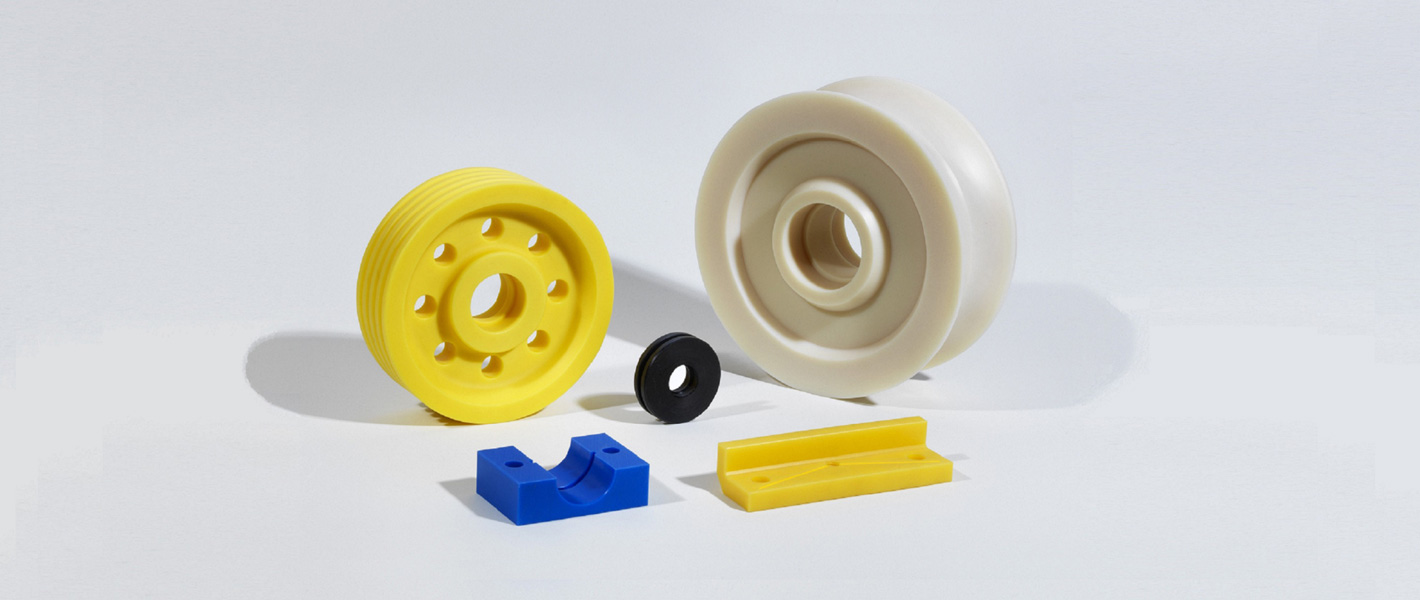

Plastic components for the shipbuilding sector

For the shipbuilding sector, ranging from yachts to mammoth ocean-going tankers, we develop and supply a wide range of plastic components to keep all parts moving as efficiently as possible.

This includes:

- Rudder shaft bearings

- Screw shaft bearings

- Cranes

- Winches (anchor windlasses and transfer winches)

- Fairleads (discs)

- FPSOs (Floating Production, Storage and Offloading units)

- ROVs (Remotely Operated Vehicles)

Friction materials for use in winches and other devices

Various winches are located onboard that are subjected to a great deal of wear and tear due to the large forces exerted on them, and because they need to be able to withstand water, wind, sand and salt. This places a great many demands on the materials. Standard components generally do not suffice. In view of our duty of confidentiality we are not in a position to specifically identify the relevant materials used. However, what we can say is that we ensure the components are made of the best possible combination of materials and shapes to guarantee a long service life.

Let us know about your needs and we will start working on developing the best possible solution for you. In addition to friction materials for winches, we also supply bearings, sliding bearings, brakes, brake parts, engineering plastics, nylon and a great deal more. We are a one-stop-shop that can supply you with all the parts you need, thus saving you a great deal of time and effort.

Plastic materials for the dredging industry

All of the parts required for the shipping industry we also supply to the dredging industry, supplemented with specific parts. This includes drop buckets for dumping rocks, elements for protecting the moving parts of grabber cranes and large buckets lined with plastic. When it comes to plastics, the product range we can supply is virtually limitless and, furthermore, we like to tackle new challenges.

Dredging offshore sites and inland waterways

A dredger is a vessel with a cutter head onboard. Cables are used to drop the cutter head to the bottom where it loosens sand and stones. A suction hose is located behind the cutter head, which sucks up the loosened material and pours it into a cargo vessel. This process can even be used to remove rocks. The vessel is stabilised using stabilising piles. The guides for these piles are lined with composites and plastics. In addition to increasing the depth of waterways and harbours, dredgers are used to create land by pumping up sand.

Dredgers carry specific deck equipment

Vessels in the dredging industry contain a wide range of rotating parts, such as screw drives, impellers and swivelling mechanisms for cranes. These parts contain sliding bearings. In addition, the vessels have a transport mechanism and carry cranes and winches. These devices are used for lifeboats among other things. All components used for hoisting contain composite sliding bearings and brakes.

Service life-related innovations

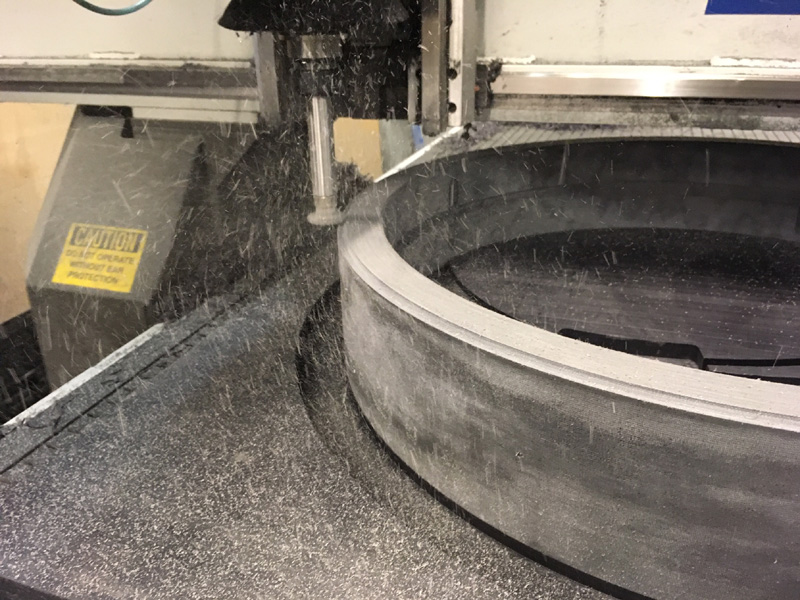

Developments in the dredging industry are primarily focused on increasing vessel size and capacity. This enables them to stay at sea for longer periods of time. Because these vessels are deployed anywhere in the world it is useful to make them as robust as possible. The longer the service life of the required materials, the less frequently the dredgers are out of commission due to maintenance work. Dredging and pumping are continuous processes that impose high demands on the system’s components.

For answers to the following questions:

What are the forces exerted on these materials and what is the expected service life? Contact us. We look forward to helping you find the most suitable plastics. Avail yourself of our 30 years of experience and expert advice in the field of plastics.

Plastic components for the offshore sector

Everything in the offshore sector is large and the sector makes use of many specific materials. All of the components used in machine construction are also applied in the offshore sector, with the additional requirement that the components must be able to withstand water, saltwater, wind and sand. Each vessel has its own particular function and consequently requires different components. They all have large moving components located above or below water that are subject to wear and tear. Dynamic plastic components are used to prevent such wear and tear. An example of this are vessels that dump rocks onto the seabed. We manufacture specific components for such rock dumping installations, known as Seatools.

Offshore Wind Turbines

Still other vessels are used to transport and install the piles on which the wind mills rest at sea. These vessels carry specific equipment. For example, the hoisting system used to straighten and place the wind turbine footings. The sliding bearings in these systems are made of high-quality plastic. In addition, we supply plastic insulation plates to combat the corrosion of the wind turbine’s footing.

Specific Logistics

Offshore logistics involve different challenges from onshore logistics. This is why many specific components are being developed. For example, for cable and pipelaying operations on the sea bed. This involves huge vessels with large reels. Components such as the special deflection wheels, discs and cable guides are made of plastic. These vessels have a complete welding line onboard to combine the pipelines into a single unit onsite. In fact, they are comprehensive plants at sea. Everything here is a magnitude greater than average. And everything is focused on preventing moving elements from wearing out.

Contributing ideas, joint development and brainstorming sessions

Offshore provides for a great contrast to standard products. We can give free reign to our creativity in this area. It keeps us focused and encourages us to continue to develop. Contact us with your requirements for offshore components and benefit from our experience and expertise.