- bearings

- spherical bearings

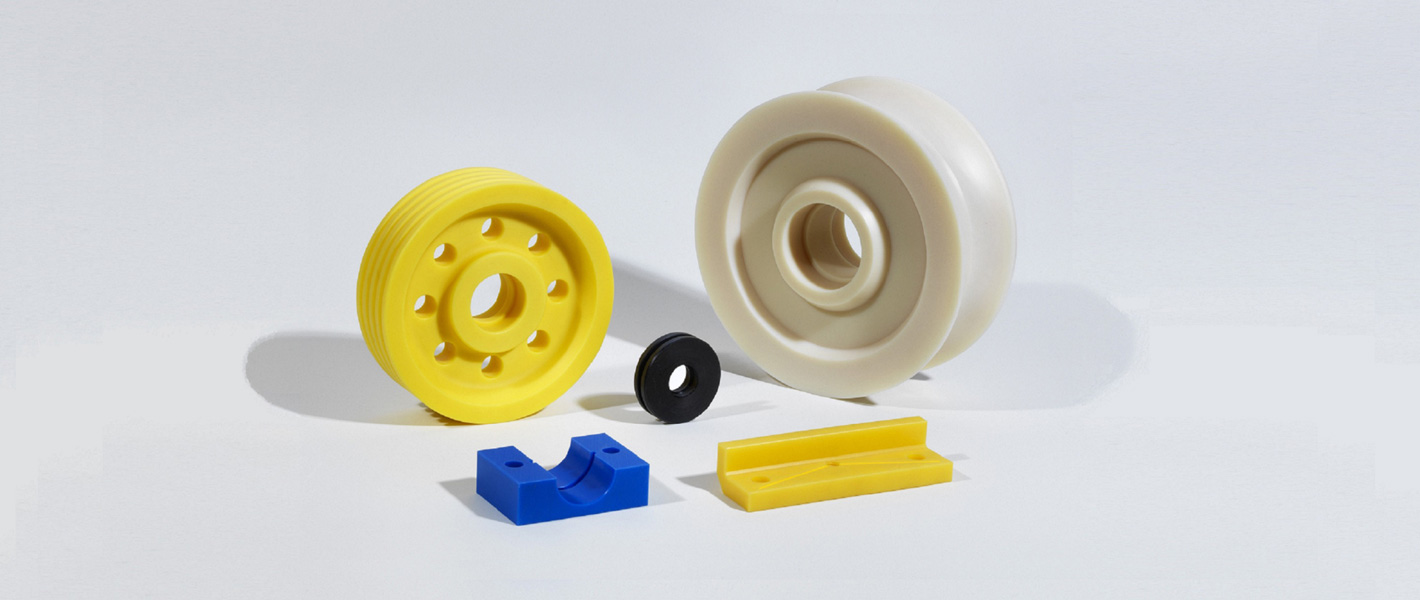

- engineering plastics

- friction material

- insulation material

In contrast to ordinary sliding bearings, spherical bearings can move in multiple directions, making them suitable for any turning-pivoting points. The presence of the spherical shape, in addition to the cylindrical shape, makes slight angular movements possible. Spherical sliding bearings are primarily used for oscillating movements in which the shaft must be self-aligning. For example in the cylinders of the drive gear of a moveable bridge and in machinery. Leakage is prevented through axial loads on the guiding device and seals of the piston rod. The spherical bearing moves in tandem with, and precisely follows, the movement of the cylinder.

Spherical Bearings benefits:

- Insensitive to variations in alignment

- Simultaneous damping of axial and radial loads

- Optimal combination of materials within the sliding plane

- Damps the piston’s motion within the cylinder

- Results in more sustainable cylinders

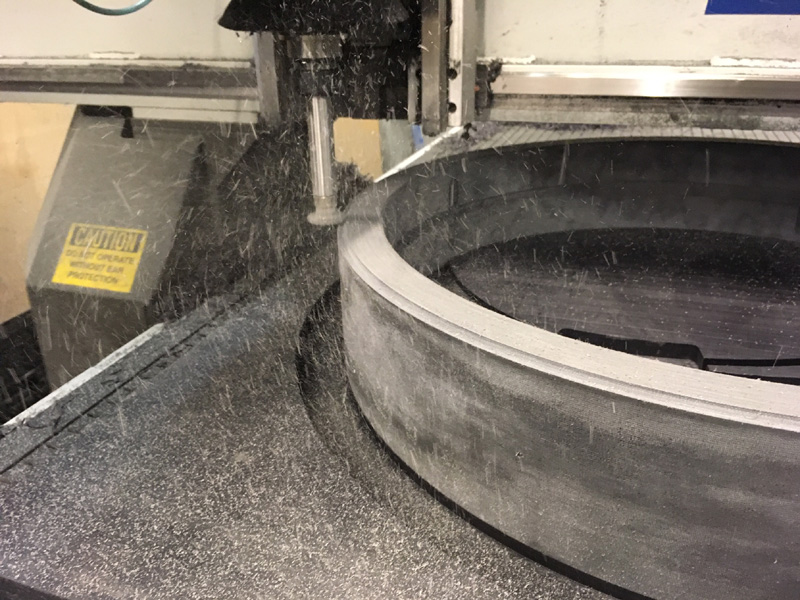

Absorbing large forces

Integrating composite materials in combination with steel makes the absorption of large forces possible and reduces the wear of the cylinders. The addition of composite materials facilitates applications in high and low temperature environments and in fresh and saltwater. Spherical bearings are generally used to replace existing, quickly wearing steel components in machinery and bridges. While the purchase cost of the original parts used generally is cheaper, they have a short service life. This results in high additional costs when a component needs to be replaced. This is because the machinery/civil work must be shut down and the replacement generally involves many person-hours of work.

Spherical bearings in accordance with the ISO 12240-1 standard

Spherical bearings are used in various areas, including bridges, locks and passenger cars, particularly in the eye rod of hydraulic cylinders. The spherical bearings developed by ASEC are used in sustainable machinery that calls for a high service life in combination with a low maintenance interval. The spherical bearings are structured modularly and are manufactured using different combinations of materials. They comply with the ISO 12240-1 standard (formerly DIN 648), as a result of which the ASEC SP bearings are directly interchangeable with standard spherical bearings. ASEC SP spherical bearings can be modified or custom designed, produced and supplied, on request.

ASEC specialises in combining different materials

ASEC in particular has developed combinations of composite and stainless steel or with another commonly used material. The composite significantly extends the service life of the dynamic component. Furthermore, this means that oil is only required during installation, which is more environmentally friendly (less oil ends up in the water) and this also results in savings. Today, various companies only use our spherical bearings in their machinery, because they opt for quality. This makes the machinery more sustainable and significantly increases its service life in comparison to machinery without spherical bearings. For that matter, this extended service life applies to all of our products.

Selecting the right spherical bearings

Prevent the accelerated wear of the essential components used in the movement of civil works. Contact us to find out which standard and custom-made spherical bearings are best suited for your bridges or locks.