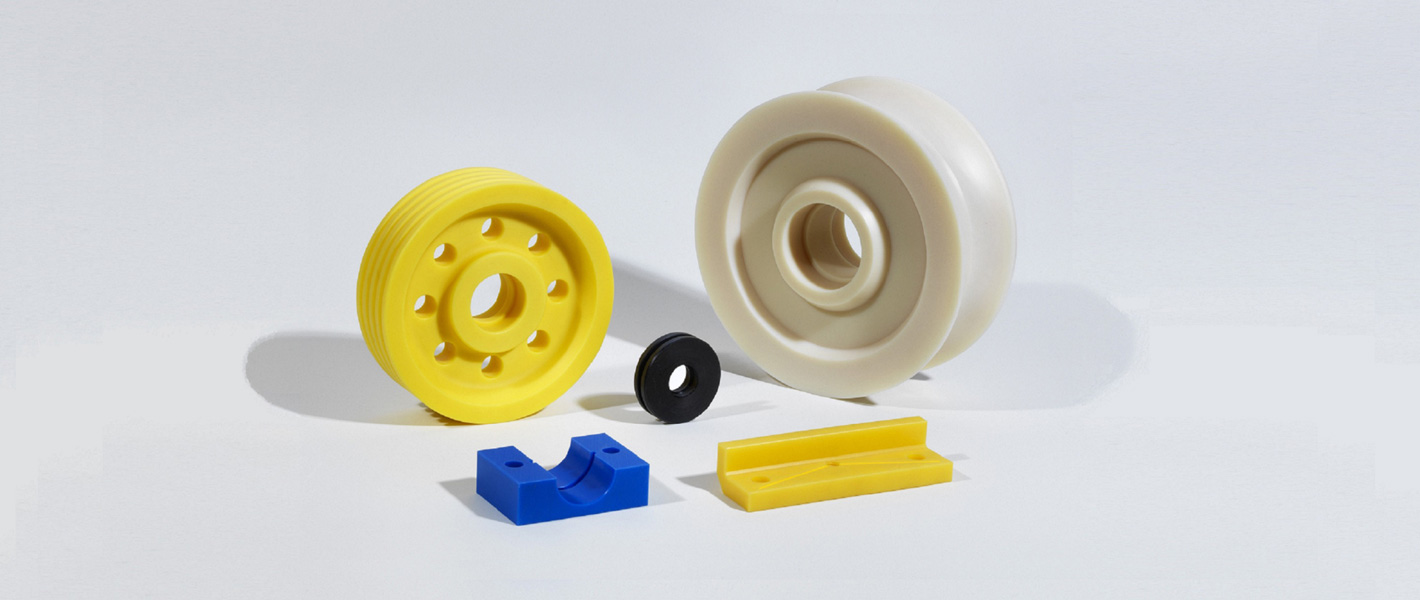

- bearings

- spherical bearings

- engineering plastics

- friction material

- insulation material

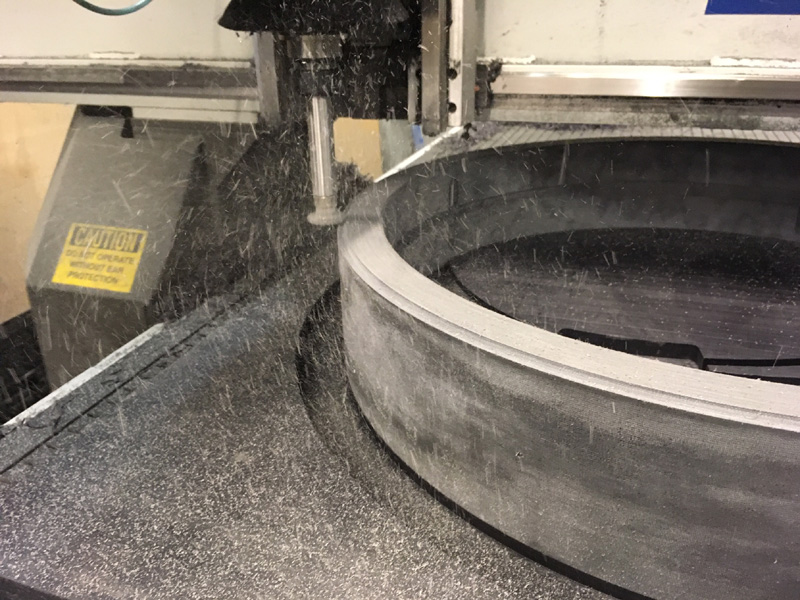

Engineering plastics are defined as all plastics with specific properties used to manufacture components that perform a certain function. These properties ensure that they are suitable for use as components that are subject to dynamic loads.

To be able to supply components of the most effective composition, we work together with 35 manufacturers throughout the world. Each of these manufacturers is a specialist in its own particular field of endeavour, as a result of which we are always able to offer a solution for a specific problem. On the basis of a drawing or an existing structure we develop a component of the best possible shape and composition. This way we are able to guarantee the longest possible service life.

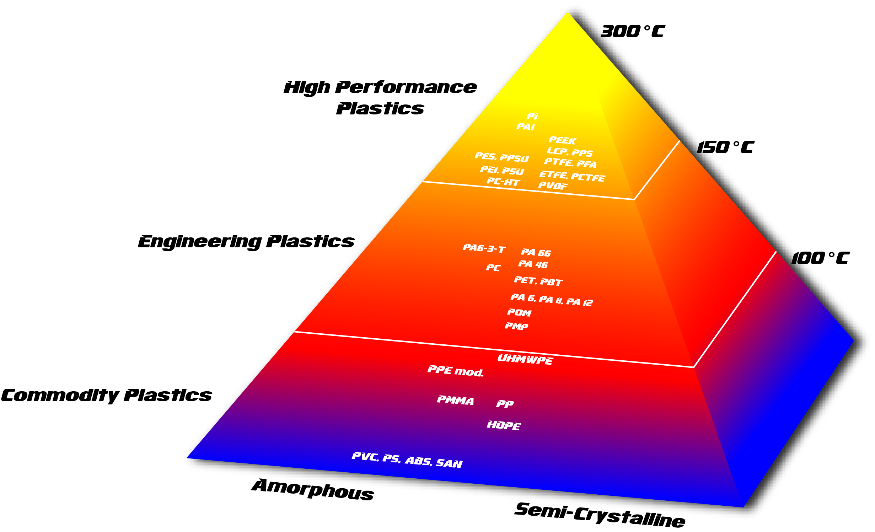

The Engineering Plastics Thermal Pyramid

Engineering plastics are classified by property, particularly thermal resistance. To clearly illustrate this, these plastics are displayed in the form of a pyramid. The most common plastics are contained at the bottom of this performance pyramid. The top of the pyramid contains special plastics with highly specific properties that can be applied under extreme conditions. These unique properties make these plastics extremely expensive. The plastics located at the top of the pyramid are only used when no useable alternatives are available within the group of plastics located lower in the pyramid.

The centre group contains special plastics that are often used. These plastics are able to withstand reasonably high temperatures in combination with specific properties relating to flexibility, UV resistance and wear resistance. The bottom group for the most part consists of commodity and recycled plastics.

Finding the right plastics

Just like engineers, we always try to select a material from the lowest possible group that meets all requirements. The reason for this is that the higher the plastic’s location in the pyramid, the more expensive it is. This does not need any further qualification. The key concern is that the selected material must be able to withstand the specified temperatures and loads for the relevant application. And that the component has a realistic service life.

Given the sustainability requirements and environmental factors, we generally end up making a selection from the centre group of plastics. A plastic from the top segment is only rarely required. Furthermore, recycled plastics from the bottom segment often suffice for structural parts.

Naturally, everyone wants the best possible material for their application. However, from a pricing perspective people are forced to look for a material lower in the pyramid that nevertheless has as many of the required properties as possible. In addition, the degree of recycling plays an increasingly larger role in the selection.

Be sure to make use of our knowledge and our contacts with specialised manufacturers so you can apply the most suitable components.