- bearings

- spherical bearings

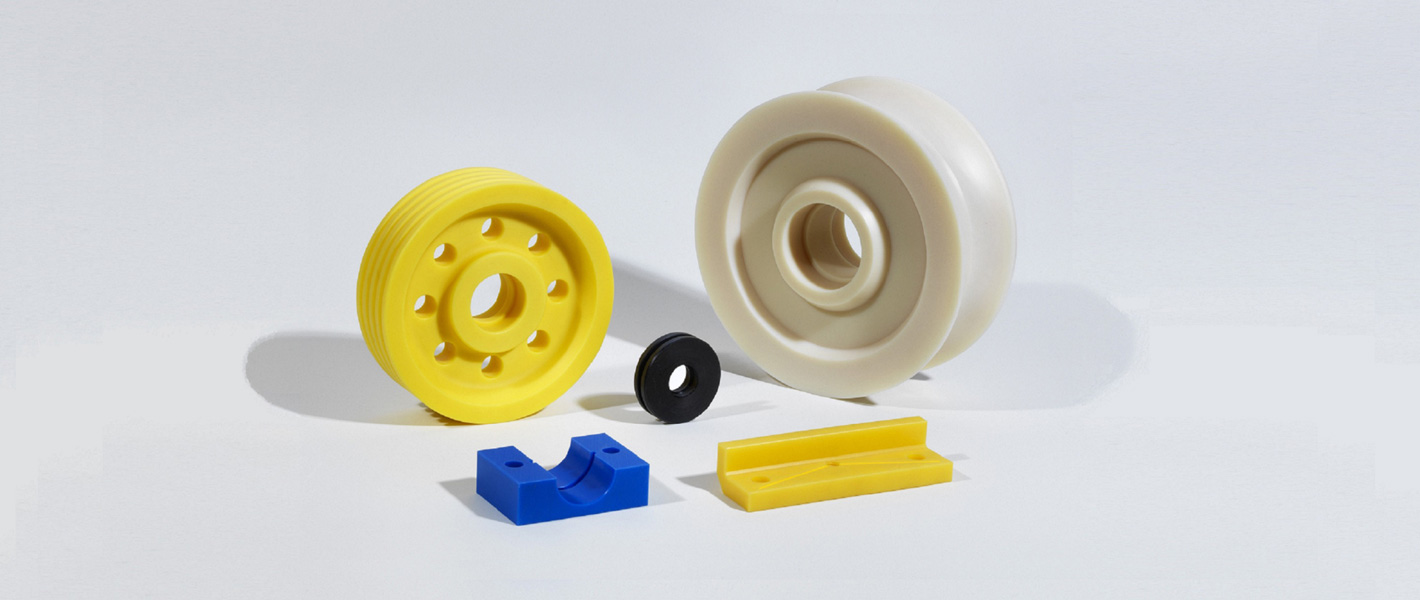

- engineering plastics

- friction material

- insulation material

Thermal Insulation

Thermal insulation products generally consist of ceramic materials or heat-resistant fibre composites and laminates with epoxy, phenol, melamine, silicone, polyester and polyimide resins.

Insulation is primarily applied in oven walls to ensure that the temperature of the liquids in the lines and tanks is maintained. Even when large distances are to be covered. The food industry and the transport of hot water in district heating systems come to mind here. On the other hand, thermal insulation ensures that areas near high-temperature tanks, machinery, channels and pipes do not become hot. Or that the area surrounding very cold liquids or other substances does not cool off.

In case of thermal insulation the components are not dynamically loaded. Plate material is often used to separate a hot or cold area. This ensures that the heat/cold does not escape to the outside or that heat/cold does not enter. This can be on a very small up to a very large scale.

ASEC exclusively supplies thermal and electrical insulation, it does not supply any sound insulation materials.

Unique solutions from a self-sufficient production chain

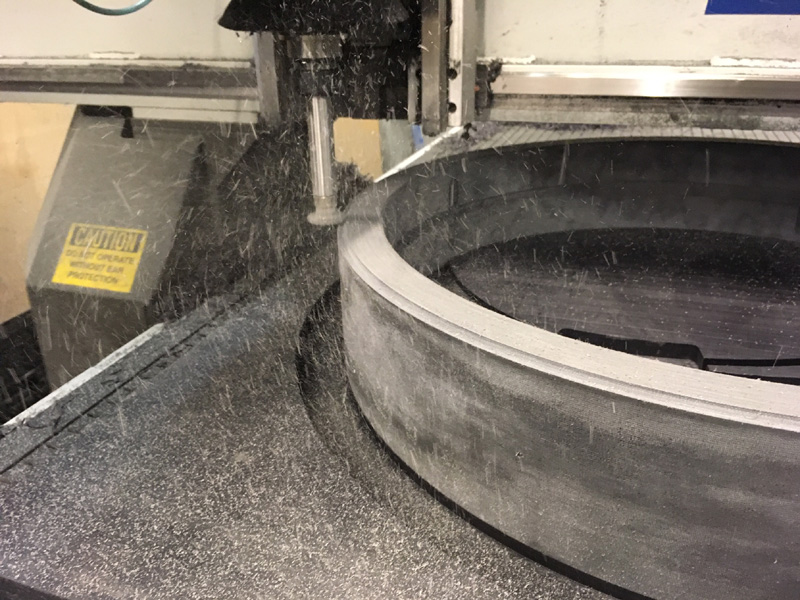

Insulating straight pipelines generally is not a problem, unless it must meet very strict criteria, such as district heating. It is far more difficult to provide very large or complex shapes with an insulating layer. If the insulating part furthermore must also be accessible, this presents an interesting challenge.

By producing high-quality plastics ourselves, we are able to offer unique solutions on the basis of a self-sufficient production chain. This means we are independent of third parties. The product range is characterised by customer-specific material properties, short delivery lead times and an excellent price-performance ratio.

Contact us with your needs for simple to complex thermal insulation and we will look for the best possible solution.

Electrical insulation to prevent transmission

Insulation materials are also used to mechanically separate parts. By taking measures to ensure there is no contact, moisture, heat or electricity cannot be transmitted. This in particular prevents the formation of corrosion. Keep in mind that corrosion is caused by a difference in electrical potential between the outside air and the material. This can be prevented through means of paint or by installing insulation. Corrosion is also created when a material is not sufficiently pure.

Electrical insulation is primarily used in the offshore and shipbuilding sectors, where there is saltwater, because this is a great conductor. By preventing different steel components from coming into contact with each other, the materials are prevented from rapidly corroding. This way the component becomes sustainable.

Ensure that you apply plastic components of the right composition, so that they do what they are meant to do and last for a long time. Avail yourself of our 30 years of experience and contact us for our expert advice.